2653 Warfield Ave., Fort Worth, TX 76106 |

exterior fire retardant plywood, exterior fire retardant wood, flame retardant wood products, exterior fire retardantT1-11 siding,exterior fire retardant decking Ft Worth - Dallas 817-658-9197 after hour |

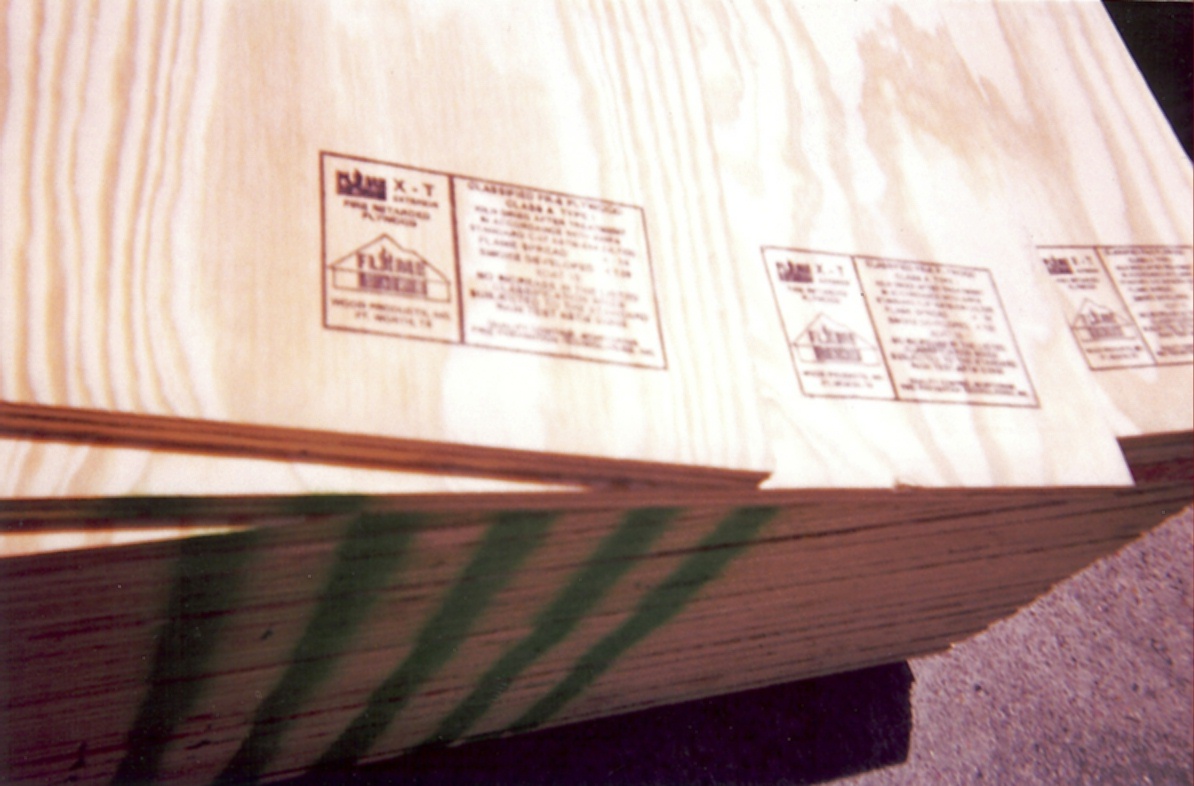

Exterior fire retardant plywood |

SDS/MSDS |

| Abilene, Dallas, Fort Worth, San Antonio, Austin, Houston, Corpus Christi, Oklahoma City, Tulsa, Kansas City, St. Louis, Texas, DFW, Odessa, Denver, Cleveland, Chicago, Miami, Pittsburgh, Atlanta, Ft Worth, FTW, Tempe, Shreveport, New Orleans, Dallas |

ALL FLAME SAFE FIRE RETARDANT PLYWOOD and FLAME SAFE FIRE RETARDANT LUMBER IS FIRE RATED FOR EXTERIOR AND INTERIOR USE - FLAME SAFE WOOD PRODUCTS HAVE THE LOWEST FIRE RATING & SMOKE DEVELOPED RATING IN THE INDUSTRY |

ASTM D2898, ASTM E84, ASTM E2768-11; CLASS A; UL723, TYPE 1; NFPA 255, TYPE 1, UBC 8-1 |

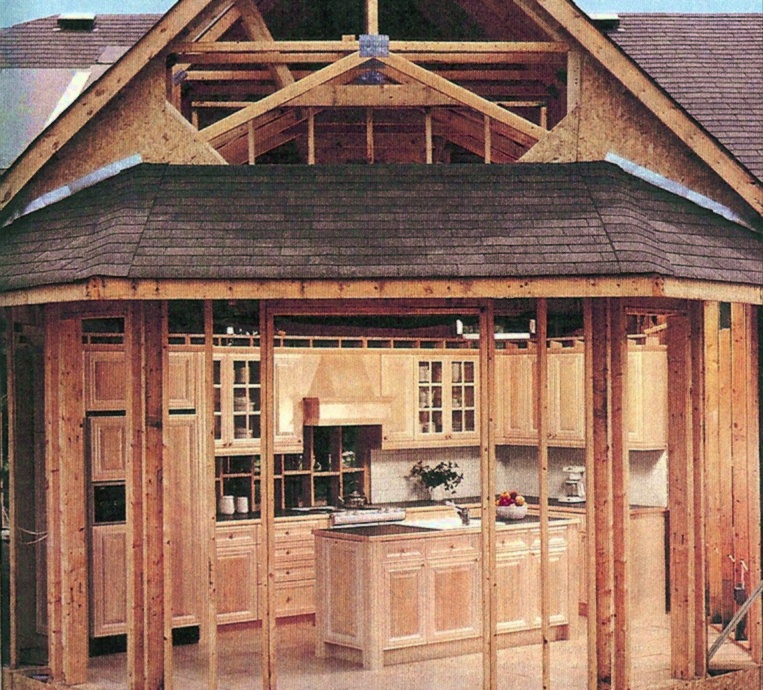

Plywood is used in many applications: commercial and residential floor, wall and roof assemblies, T1-11 siding, exterior decking, fencing, packages and boxes,scaffolding materials, signs, marine. Manufacturing process of plywood: A log of wood is softened with steam and then shaved into thin veneers (also referred to as plies). The thin veneers are allowed to dry and then coated with an adhesive. Each ply is laid in such a way that the grain direction of each ply is opposite to the ones above and below it. There are usually an odd number of plies so that the sheet is balanced. The entire stack is then treated in a hot press at high temperature and pressure to form plywood. Plywood is resistant to cracking, shrinkage, splitting, twisting/warping and has a high degree of strength. Pound for pound, plywood is stronger than steel in static bending strength. |

| Grade | Description | Grade | Description |

| A/B | Sanded face veneers practically free from all defects. Reverse veneers with only a few small knots or discoloration | B/C | Sanded face veneer with only a few small knots or discoloration. Reverse side permitting ointed veneers, large knots, plugs, etc. |

| A/C | Sanded one, reverse side permitting jointed veneers, large knots, plugs, etc. | CDX | Knots, knotholes, cracks, and all other defects permitted |

| Fire Retardant Softwood Plywood: Douglas Fir, Southern yellow pine (SYP), -Typically used for commercial construction - wall, floor, roof sheathing and backer board, - usually CDX grade |

| Fire Retardant Hardwood Plywood: Ash, Birch, oak, mahogany-excellent strength, stiffness and resistance to creep - it has a high planar shear strength and impact resistance, which makes it especially suitable for wall panels,cabinets and trim |

| Fire Retardant Aircraft Plywood: Birch, oak, mahogany, other species available- high strength plywood |

| Fire Retardant Marine Plywood: Marine plywood is manufactured from durable face and core veneers, with few defects so it performs longer in humid and wet conditions and resists delaminating and fungal attack - used in docks & boats |

|

Flame Safe plywood is kiln dried to a moisture content not to exceed 15%. |

|

| Inherent Flame Spread Rating for Plywood vs. Flame Safe Treated Plywood |

| Size | Material | Untreated Flame Spread | Flame Safe Fire Retardant Treated | Size | Material | Untreated Flame Spread | Flame Safe Fire Retardant Treated |

| SOFTWOOD PLYWOOD - Exterior glue(eg) | HARDWOOD PLYWOOD | ||||||

| 3/8" | Cedar | 70-95 | <5 | 3/4" | Ash-P core | 134 | <25 |

| 5/8" | 70-95 | <5 | 1/4" | Birch-V core | 135-173 | <25 | |

| 1/4 | Douglas Fir | 150 | <5 | 1/4" | Birch-Fuma V | 127 | <25 |

| 3/8" | 110-150 | <5 | 3/4" | Birch-DF V C | 114 | <25 | |

| 1/2" | 130-150 | <5 | 3/4" | Birch-High Density V C | 114 | <25 | |

| 5/8" | 95-130 | <5 | 3/4" | Birch-P C | 124 | <25 | |

| 3/8" | Hemlock | 75-160 | <5 | 3/4" | Birch-MDF C | 134 | <25 |

| 1/4" | Southern Pine | 95-110 | <5 | 3/4" | Honduras Mahogany-P C | 105 | <25 |

| 3/8" | 100-105 | <5 | 11/64" | Lauan | 167 | <25 | |

| 5/8" | 90 | <5 | 1/4" | 150 | <25 | ||

| 3/8" | Redwood | 95 | <5 | 1/4" | Oak-DF V core | 153 | <25 |

| 5/8" | 75 | <5 | 3/4" | Oak-MDF core | 123 | <25 | |

| 3/8" | Medium Density Fiberboard MDF | 140 | <25 | 3/16" | Particleboard | 156 | <25 |

| 7/16" | 125 | <25 | 3/8" | 200 | <25 | ||

| 5/8" | 120 | <25 | 1/2" | 135-156 | <25 | ||

| 11/16" | 140 | <25 | 5/8" | 153 | <25 | ||

| 3/4" | 130-140 | <25 | 11/16" | 168 | <25 | ||

| 1" | 90 | <25 | 3/4" | 145 | <25 | ||

| 3/4" | P-board (eg) | 88-98 | <25 | ||||

Particle Core - P C Veneer Core - V C P-board - Partcleboard |

|||||||

| 7/16" | Oriented Strand Board OSB | 127-138 | 0 ext 8.4 | ||||

| 5/8" | 86-150 | 0 ext 8.4 | |||||

| 3/4" | 74-172 | 0 ext 8.4 | |||||

| 1-1/8" | 147-158 | 0 ext 8.4 | |||||

ALLOWABLE SPANS AND LOADS FOR PLYWOOD AND STRUCTURAL PANELS FOR ROOF AND SUBFLOOR For ROOF and SUBFLOOR SHEATHING AND COMINATION SUBFLOOR UNDERLAYMENT *1,2,3 |

||||||

| Span Rating | Thickness (inch) | Max. Span (inches) *4 |

Load (lbs./ sq. ft. at maximum span |

Maximum Span (inches) |

||

| with edge support | Without edge support | Total Load | Live Load | |||

| CD, CC Sheathing *5 | ROOF *6 |

Subfloor *6 | ||||

| 12/0 | 5/16 | 12 | 12 | 40 | 30 | 0 |

| 16/0 | 5/16, 3/8 | 16 | 16 | 40 | 30 | 0 |

| 20/0 | 5/16, 3/8 | 20 | 20 | 40 | 30 | 0 |

| 24/0 | 3/8, 7/16, 1/2 | 24 | 20 *7 | 40 | 30 | 0 |

| 24/16 | 7/16, 1/2 | 24 | 24 | 50 | 40 | 16 |

| 32/16 | 15/32, 1/2, 5/8 | 32 | 28 | 40 | 30 | 16 *8 |

| 40/20 | 19/32,5/8,3/4,7/8 | 40 | 32 | 40 | 30 | 20 *8,9 |

| 48/24 | 23/32, 3/4, 7/8 | 48 | 36 | 45 | 35 | 24 |

| Underlayment, C-C Plugged, Single floor *10 | ROOF *6 |

Combination Subfloor Underlayment *11 | ||||

| 16 o.c. | 19/32, 5/8 | 24 | 24 | 50 | 40 | 16 *8 |

| 20 o.c. | 19/32/ 5/8, 3/4 | 32 | 32 | 40 | 30 | 20 *8,9 |

| 24 o.c. | 23/32, 3/4 | 48 | 36 | 35 | 25 | 24 |

| 32 o.c. | 7/8, 1 | 48 | 40 | 50 | 40 | 32 |

| 48 o.c. | 1-3/32, 1-1/8 | 60 | 48 | 50 | 40 | 48 |

| For SI: 1inch = 25.4mm, 1psf = 0.0479kNm *1 The allowable loads were determined using a dead load of 10 psf. - if the dead load exceeds 10 psf, then the live load shall be reduced accordingly *2 Panels continuous over two or more spans with long dimension perpendicular to supports. Spans shall be limited to values shown because of possible effect of concentrated loads. *3 Applies to panels 24" or wider *4 Lumber blocking, panel edge clips (one midway between each support, except to equally spaced between supports when span is 48 inches), tongue & groove panel edges, or other approved type of edge support *5 Includes Structural 1 panels in these grades *6 Uniform load deflection limitation: 1/180 of span under live load plus dead load, 1/240 of span under live load only *7 Maximum span 24 inches for ½" panels *8 Maximum span 24 inches where 3/4" wood finish flooring is installed at right angles to joists *9 Maximum span 24 inches where 1-1/2" of lightweight concrete or approved cellular concrete is placed over the subfloor *10 Unsupported edges shall have tongue & groove joints or shall be supported whith blocking unless nominal 1/4" thick underlayment or 1-1/2" of lightweight concrete or approved cellular concrete is placed over the subfloor, or 3/4" wood finish flooring is used. Allowable uniform live load at maximum span, based on deflection of 1/360 of span, is 100 psf *11 Unsupported edges shall have tongue & groove joints or shall be supported by blocking unless nominal 1/4" thick underlayment or 3'4" wood finish flooring is used. Allowable uniform live load at maximum span, based on deflection of 1/360 of span, is 100psf, except panels with a span rating of 48 o.c. are limited to 65 psf total uniform load at maximum spdan |

Fire Retardant Plywood & Fire Retardant Wood Treatments

Vacuum Pressure Impregnation and Kiln Dried After Treatment (KDAT)

Fire rated plywood ● Fire rated wood ●Fire rated lumber ●Fire rated timber

Exterior fire retardant lumber ● interior fire retardant lumber ● exterior fire retardant plywood ● interior fire retardant plywood ● interior fire retardant wood specialties ● exterior fire retardant wood specialties ● exterior fire retardant timbers ● interior fire retardant timber ● architectural millwork, molding & trim ● fire retardant OSB(oriented strand board) ● fire retardant I-joists ● fire retardant particle board ● fire retardant MDF(medium density fiberboard) ●exterior fire retardant 5/8" T1-11 siding ●exterior fire retardant 3/8" T1-11 siding ● exterior fire retardant decking ● interior t1-11 ● fire retardant shingles ● fire retardant Insulation ● fire retardant treated special orders

|

EXTERIOR FIRE RETARDANT PLYWOOD & LUMBER For those specifications that call for an exterior fire retardant lumber or plywood that will have exposure to the elements or high humidity conditions Flame Safe XT is the product of choice. In addition to passing the ASTM E84 test for surface burning characteristics, which all exterior fire retardant lumber and plywood bearing a Class I stamp must pass, Flame Safe XT has passed the ASTM D2898 accelerated weathering (rain) test as well. Flame Safe XT has a clear finish which can be stained with a water based stain or painted with a latex based paint. Flame Safe XT can be specified with preservative and decay resistant treatments such as MCA, ACQ, CCA and may be specified with a water repellant is so desired. Applications such as exterior decks, balconies, stairs or siding are the notable examples of where Flame Safe XTand preservative treated would be the logical choice |

PROPERTIES OF FLAME SAFE FIRE RETARDANT TREATED PLYWOOD & LUMBER |

Permanence: Flame Safe interior fire retardant treated lumber and plywood is a permanent guard against the spread of flame

Strength: Flame Safe's aqueous based resin fire retardant treatment and kiln-drying process strengthens the wood

Hygroscopicity: Flame Safe's exterior and interior fire retardant plywood and lumber is no more hygroscopic than untreated wood of any given species

Corrosion: Flame Safe exterior and interior fire retardant plywood and lumber does not demonstrate any greater corrosion rate than untreated wood on metal fasteners or hardware

Decorating and Finishing: Flame Safe exterior and interior fire retardant plywood and lumber surfaces can be stained and painted with ordinary preparation, however avoid using lacquer based stains or varnishes

Field Cuts: Flame Safe exterior and interior fire retardant plywood and wood allows the user to re-surface, mill, or rip lumber or plywood without effecting the fire rating.

Versatility: Flame Safe exterior and interior fire retardant plywood and lumber is compatible with most waterborne preservative treatments for lumber, plywood and timber for exterior and in ground use.

WARNING: All exterior flame retardant lumber and plywood is subjected to the ASTM D2898 prior to the ASTM E84 testing, any claims of having exterior flame retardant lumber or plywood without having gone through the required test procedure would be a false claim. Beware of companies who claim that their wood products have been sumitted to the ASTM D2898 procedure, because 'submission' does not mean that it has 'passed' the ASTM E84 and the ASTM D2898 tests. Their statements are false and misleading. Always ask for the complete accredited testing laboratory test reports for verification. Any doubts call 1-800-333-9197 |

Flame Safe Wood Products vacuum pressure impregnated fire retardant plywood, fire retardant lumber, and fire retardant wood and Flame Safe Chemical’s fire retardant products have been tested by accredited third party testing agencies. Flame Safe warrants it’s products to perform as tested and will furnish test reports upon request, in addition to those published on our web site.

In addition, Flame Safe Chemical manufactures a complete line of fire retardant coatings, fire retardant penetrants and fire retardant sprays that meet or exceed industry’s fireproofing standards. The effectiveness of Flame Safe’s fire retardant products are well documented.

The uniqueness of Flame Safe’s fire retardant products are not only their simplicity of application, their low cost, their environmental safeness, their tested, proven certifications, but most importantly they are required by code. Fire codes are written and enforced to save lives and property.

Flame Safe is dedicated to setting not merely following the fireproof industry standards through ongoing research development and testing programs. Flame Safe continually endeavors to educate the marketplace on the significance of fireproofing combustible materials through the use of fire retardant products.

FIRE PREVENTION IS THE BEST PROTECTION |

| Fire is the most unpredictable and dangerous accidents that may occur in our environment. Ignition is one of the essentail fire properties of a material. The time to ignition depends of the species, moisture content, inherent variability of wood as a natural material. Once ignition has occurred, a layer of char is formed as the wood burns. The wood is converted to charcoal which has no strength. |

.jpg) |

Uniquely, Flame Safe’s fire retardant coatings, sprays and penetrants are easily applied, colorless, non-toxic, environmentally safe, and are aqueous based fire retardants chemicals. Flame Safe has both interior and exterior fire protection coatings, penetrants, and fire retardant sprays for wood, wood products, architectural millwork, molding and trim, lumber, plywood, wood shingles, timbers, fiberglass and plastics, fabric, theater curtains, drapes, upholstery, carpet, mattresses and bedding, wall coverings, thatch, thatching, tiki huts, paper, cardboard and packaging systems for combustible liquids. The Fire Buster™ is a fire retardant treated fabric available for commercial and residential use. |

| Flame Safe's fire retardant coatings, flame retardant sprays meet building code requirements as a CLASS A fire retardant coating meeting the ASTM E84; UL 723, and NFPA 255 - Surface Burning Characteristic of Building Materials | |

|

|

FEMA PARTNER |

|

UL Tested |  W/N 21045 W/N 21045 |

W/N 21051 W/N 21051 |

|---|

Steinner Tunnel ASTM E84 Class A UL723, Type 1 NFPA255, Type 1 Steinner Tunnel ASTM E84 Class A UL723, Type 1 NFPA255, Type 1 |

Click here for more information on

Flame Safe Wood Products

Exterior and Interior Fire Retardant Plywood

Fire Retardant Wood - - Fire Retardant Treated Lumber - - Fire Retardant Timber & Timbers

Fire Rated

Wood, Fire Rated

Plywood, Fire Rated

Lumber and Fire Rated

Timber & Timbers

and

Flame Safe Chemical Corporation´s

Fire Retardant Spray on Coatings, Penetrants

Flame Safe Manufactures the most effective fire retardant coatings and sprays to fireproof fabric and fabrics for theatrical curtains, upholstery, canvas tents, mattresses, clothing, carpet, wall coverings, paper, cardboard, lumber, wood, plywood, timber and timbers, thatch & thatching, Tiki huts, grass, brush, and fire retardant spray for Christmas trees

2653 Warfield Avenue, Fort Worth, Texas 76106

Phone: 1-800-333-9197 or 1-817-740-9197

The information contained herein is the property of Flame Safe Chemical Corporation and Flame Safe Wood Products, Inc . copyright 1990 Revised 8/20/2009

Montgomery,Alabama; Birmingham, AL; Huntsville, Alabama; Mobile, Alabama; Tuscaloosa, AL; Anchorage, Alaska; Fairbanks, Alaska; Kodiak, Alaska; Juneau, Alaska; Flagstaff, Aizona; Grand Canyon, AZ; Phoenix, Arizona; Tuscan, Arizona; Yuma, AZ; Camden, AR; Little Rock,Arkansas; Fayetteville, Arkansas; Fort Smith, Arkansas; Texarkana; AR; Anaheim, California; Bakersfield, CA; Bishop, CA; Fresno, CA; Irvine, CA; Long Beach, California; Los Angeles, CaliTallahassee, fornia; Oakland, CA; Modesto, CA; Monterey, CA; Oakland, California; Oxnard, CA; Palm Springs, CA; Pasedena, California; Fredding, CA; San Diego, CA; Sacramento, California; San Francisco, California; San Jose, CA; Santa Barbara, California; South Lake Tahoe, CA; Stockton, Calfornia; Aspen, Colorado; Denver,Colorado Colorado Springs, Colorado; Durango, CO; Fort Collins, CO; Grand Junction, CO; Gunnison, Colorado; Lamar, CO; Montrose, Colorado; Pueblo, CO; Steamboat Springs, CO; Telluride, Colorado; Bridgeport, CT; New Haven, Connecticut; New London, CT; Hartford,Connecticut; Dover, Delaware; Willmingon, Delaware; Washington DC; Daytona Beach, Florida; Fort Lauderdale, FL; Fort Meyers, Florida, Fort Walton Beach, FL; Gainesville, Florida; Jacksonville, FL; Key West, Florida; Melbourne, FL; Miami, Florida; Naples, FL; Orlando, Florida; Panama City, FL; Pensacola, Florida; St. Petersburg, FL; Sanford, FL; Sarasota, Florida; Tallahassee, Florida; Tampa, Fl; West Palm Beach, Florida; Clearwater, Fl; South Beach, FL; Albany, GA; Athens, Georgia; Atlanta, Georgia; Augusta, Georgia; Columbus, GA; Macon, Georgia; Savannah, Georgia; Valdosta, GA; Hilo, HI; Honolulu, Hawaii, Hoolehua, Hawaii; Kahului. HI; Kaailua Kona, HI; Kamuela, Hawaii, Kapalua, Hawaii; Lanai City, HI; Lihue, HI; Princeville, Hawaii; Boise, Idaho; Coeur d'Alene, Idaho; Idaho Falls, Idaho; Lewiston, ID; Sun Valley, Idaho; Twin Falls, Idaho; Aurora, IL; Bloomington, IL; Champaign, Illinois; Chicago, Illinois; Danville, IL; Marion, Illinois; Marion, Illinois; Mount Vernon, IL; Peoria, Illinois; Quincy, IL; Rockford, IL; Springfield, Illinois, Sterling, IL; Wheeling, Illinois; Bloomington, Indiana, Butler, IN; Evansville, Indiana; Fort Wayne, IN; Gary, Indianna; Indianapolis, Indiana; Lafeyette, IN; South Bend, Indiana; Terre Haute, Indiana; Burlington, Iowa; Cedar Rapids, Iowa; Des Moines. Iowa; Dubuque, Iowa; Fort Dodge, Iowa; Mason City, IA; Mason City, IA; Sioux City, Iowa; Waterloo, Iowa; Dodge City, Kansas; Garden City, KS; Great Bend, KS; Hays, Kansas; Manhattan, Kansas; Salina, Kansas; Topeka, Kansas, Wichita, KS; Kansas City, Kansas; Lexington, Kentucky; Louisville, Kentucky; Owensboro, KY; Paducah, KY; Alexandria, LA; Baton Rouge, Louisiana; Lafeyette, Louisiana; Lake Charles, LA; Monroe, LA; New Orleans, Louisiana; Shreveport, Louisiana; Augusta, Maine; Bangor, Maine; Bar Harbor, ME, Portland, Maine; Rockland, Maine; Annapolis, Maryland; Baltimore, Maryland; Cumberland, MD, Hagerstown, MD; Ocean City, Maryland; Salisbury, MD; Boston, Massachusetts; Edgartown, MA; Hyannis, Masschusetts, Hyannis, MA Lawrence, MA; Nantucket, Massachusetts;New Bedford, MA; Plymouth, MA; Massachusetts; Providence, Massachusetts; Springfield, MA; Worcester, Masschusetts; Battle Creek, Michigan; Detroit, Michigan; Flint, Michigan; Grand Rapids, hancock, Iron Mountain, Kalamazoo, Lansing, Marquette, Menominee, Muskegon, Pellston, Pontiac, Saginaw, Traverse City, Michigan; Bemidji, Minnesosta; Brainerd, Duluth, Fairmont Fergua, Grand Rapids, Hibbing, International Falls, Minneapolis, Minnesota; Rochester, Thief River Falls, Minnesota; Columbus, Mississippi; Corinth, Greenville, Gulfport, Jackson, Mississippi; Laurel, Meridan, Tupelo, Mississippi; Cape Girardeau, Missouri; Columbia, Joplin, Kansas City, Missouri; Kirksville, St Louis, Missouri; Springfield, Missouri; Billings, MT; Bozeman, MT; Butte, Montana, Glasgow, MT; Great Falls, Montana; Helena, Montana, Kalispell, MT; Lewistown, MT; Miles City, Montana; Missoula, Montana; West Yellowstone, Montana; Wolf Point, MT; Allaince, Nebraska; Chadron, Grand Island, Nebraska; Hastings, Kearney, Lincoln, Nebraska; Norfolk, North Platte, NE; Omaha, Nebraska; Scottsbluff, NE; Sidney, Nebraska; Elko, Neveda; Ely, NV; Las Vegas, Nevada; Reno, NV; Keene, NewHampshire; Laconia, NH; Lebanon, New Hampshire; Manchester, New Hampshire; Atlanctic City, New Jersey; Newark, NJ; Trenton, New Jersey; Albuquerque, New Mexico; Carlsbad, NM, Clovis, New Mexico; Farmington, New Mexico, Gallup, NM; Los Alamos, NM; Roswell, New Mexico, Santa Fe, New Mexico; Albany, New York;, Buffalo, Inslip, New dYork; Ithaca, NY; Jamestown, New York, Long Island City, NY, Newyork, New York, Niagra Falls, NY; Plattsburgh, NY; Rochester, NY, Syracuse, New York; Utica, New York, Watertown, NY; White Plains, New York; Charlotte, North Carolina, Fayetteville, NC; Greensboro, North Caroling; Jacksonville, NC; Kinston, NC; ManteNC; Pinehurst, NC; Raleigh, North Carolina; Willmington, North Carolina; Winston-Salem, North Carolina; Bismark, North Dakota; Fargo, ND; Grand Forks, ND; Jamestown, North Dakota; Minot, ND; Williston, North Dakota; Akron, Ohio, Cicinnati, Ohio; Cleveland, OH; Columbus, Ohio; Dayton, Ohio, Toledo, OH; Wilmington, OH, Youngstown, Ohio; Enid, Oklahoma; Lawton, OK; McAlester, OK; Oklahoma City, Oklahoma; Ponca City, OK; Tulsa, Oklahoma; Eugene, Oregon; Klamath Falls, Oregon, Medford, North Bend, Pendletoon, Portland, Oregon; Redmond, OR; Salem, Oregon; Allentown, Pennsylvania; Bradford, PA; Du Bois, PA; Erie, Pennsylvania; Franklin, PA; Harrisbug, PA; Lancaster, PA; Philadelphia, Pennsylvania; Pittsburg, PA, Reading, PA, Williamsport, Pennsylvania; Block Island, Rhode Island; ; Providence, RI; Westerly, Rhode Island; Anderson, South Carolina; Charleston, South Carolina; Columbia, South Carolina; Florence, SC; Greenville, SC; Hilton Head Island, SC; Myrtle Beach, South Carolina; Aberdeen, South Dakota; Brookings, SD; Huron, South Dakota; Rapid City, SD; Sioux Falls, South Dakota; Watertown, SD; Chattanooga, Tennessee; Jackson, TN; Knoxville, Tennessee;, Memphis, Tennessee; Nashville, Tennessee; Abilene, Texas,Amarillo, TX; Austin, Texas; Beaumont, TX; Brownsville, Texas; College Station, TX; Corpus Christi, Texas; Dallas, El Paso, TX; Fort Worth, Texas; Houston, Texas; Killeen, TX; Laredo, TX; Longview, Texas; Lubbock, TX; Lufkin, TX; McAllen, TX; Midland, Texas, Odessa, TX; Paris, Texas; San Angelo, TX; San Antonio, Texas; Tyler, TX; Waco, Texas; Wichita Falls, Texas; Blanding Utah; Cedar City, Utah; Delta, UT; Fillmore, UT; Kanab, UT; Milford, UT; Monticello, Utah; Mount Pleasant, Utah; Nephi, UT; Price, UT; Richfield, UT; Roosevelt, Utah; St.George, Utah; Salina, UT; Salt Lake City, Utah; Wendover, Utah; Burlington, Vermont; Rutland, Vermont; Charlottesville, Virginia; Danville, VA; Hot Springs, VA; Lynchburg, Virginia; Newport News, Virginia; Richmond, VA; Roanoke, Virginia; Anacores, Washington; Bellingham, WA; Center Island, WA; DEcatur, Washington. Eastsound, WA; Friday Harbor, WA, Kenmore, W, Lopez, Washington; Moses Lake, Washington; Oak Harbor, Port Angeles, Washington; Richland, WA; Roche Harbor, WA; Seattle, Washington; Spokane, Washington; Stuart Islsand, WA; Waldron, WA; Walla Walla, Wahington; West Sound, Washington, Yakima, Washington; Beckley, West Virgina; Bluefield, WV; Charleston, WV; Clarksburg, West Virgina; Elkins, WV; Greenbriar, WV; Huntington, West Virgina; Morgantown, West Virginia; Parkersburg, West Virginia; Appleton, Wisconsin; Eagle River, Eau Claire, Wisconsin; Green Bay, Wisconsin, Janesville, LaCrosse, Wisconsin; Madison, Wisconsin; Milwaukee, Wisconsin. Oshkosh, Wisconsin; Rhinelander, Wisconsin; Ssturgeon, Wisconsin; Wausau, Wisconsin; Casper Wyoming; Cheyenne, Wyoming; Cody, WY; Gillette, WY; Jackson, Wyoming; Laramie, WY; Riverton, WY; Rock Springs, Wyoming; Sheridan, Wyoming; Worland, Wyoming; Nassau, Bahamas; San Juan, Pueto Rico; Charlotte Amalie, Virgin Islands; St. Thomas; St. Croix; Edmonton, Alberta, Cananda; Victoria, British Columbia, Canada; Winnepeg, Manitoba, Canada; Fredericton, New Brunswick, Canada; Saint John's Mewfoundland, Canada; Yellowknife, Northwest Territories, Canada; Halifax, Nova Scotia, Canada; London, Ottawa, Toronto, Ontario, Canada; Charlottetown, Prince Edward Island

flamesafeplywood.com

flamesafeplywood.com